2025 Guide: How to Choose the Best Commercial Heat Sealer Machine

In the rapidly evolving world of packaging technology, selecting the right commercial heat sealer machine can significantly impact operational efficiency and product integrity. According to industry expert Dr. Emily Carter, a seasoned packaging engineer, "Choosing the appropriate commercial heat sealer machine is crucial for ensuring optimal sealing performance and enhancing product shelf life." Her insights highlight the importance of understanding the specific needs of your operation, whether you are sealing food products, pharmaceuticals, or other industrial materials.

As businesses strive to maintain high standards of quality while managing costs, the decision-making process for a commercial heat sealer machine becomes increasingly complex. Factors such as sealing speed, temperature control, and compatibility with various materials are essential to consider. Furthermore, advancements in technology have introduced innovative features that cater to diverse applications, making it imperative for companies to stay informed about the latest developments in this field. This guide aims to elucidate the key considerations and expert recommendations to help you navigate the selection process effectively, ensuring that your investment in a commercial heat sealer machine meets and exceeds your operational goals.

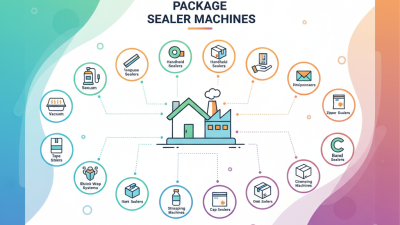

Understanding Different Types of Commercial Heat Sealers Available

When selecting the best commercial heat sealer machine, it’s crucial to understand the various types available to meet your specific sealing needs. Heat sealers can be broadly categorized into several types including impulse sealers, constant heat sealers, and vacuum sealers. Each type operates differently and serves unique purposes, offering varied advantages based on the application. Impulse sealers, for instance, are ideal for quick, low-volume sealing tasks, providing a strong seal without requiring prolonged heating. Constant heat sealers, on the other hand, are excellent for higher volume production, ensuring a consistent and uniform seal across various materials.

**Tips:** When choosing a heat sealer, consider your production volume and the types of materials you’ll be sealing. If you're dealing with delicate products, an impulse sealer might be the best choice, as it minimizes the risk of heat damage. For businesses that require airtight packaging, investing in a vacuum sealer could enhance product longevity.

Another critical factor to examine is the sealing width and thickness your machines can accommodate. Some heat sealers are designed for thinner materials while others are built for heavy-duty applications. Always ensure that the machine you select aligns perfectly with your operational requirements.

**Tips:** Research the specifications and features of each heat sealing machine, including their maximum seal width and thermal capabilities. Doing so will help you avoid purchasing a machine that may fall short of your sealing needs, ultimately saving time and resources.

2025 Guide: How to Choose the Best Commercial Heat Sealer Machine

| Type |

Sealing Width |

Power (W) |

Seal Speed (m/min) |

Weight (kg) |

Material Compatibility |

Price Range ($) |

| Impulse Heat Sealer |

200 mm |

300 |

0.8 |

2.5 |

Polyethylene, Polypropylene |

50 - 150 |

| Constant Heat Sealer |

300 mm |

600 |

1.5 |

5.0 |

Foil, Polyethylene |

100 - 250 |

| Vacuum Heat Sealer |

400 mm |

800 |

2.0 |

8.0 |

Barrier Film, Mylar |

250 - 500 |

| Foot Pedal Sealer |

250 mm |

400 |

1.2 |

4.0 |

Polyethylene, Polypropylene |

75 - 200 |

Key Features to Consider When Selecting a Heat Sealer Machine

When selecting a commercial heat sealer machine, several key features should be taken into careful consideration to ensure you choose the best fit for your needs. First, consider the sealing capacity of the machine. This refers to the width and thickness of the materials it can seal. For high-volume production, opt for a model that offers a broader sealing area and can handle thicker materials. Additionally, look for flexibility in operating modes; some machines allow for both continuous and intermittent sealing, which can be advantageous depending on your production demands.

Another crucial feature is temperature control. A reliable heat sealer should have adjustable temperature settings that cater to the specific materials you are working with, ensuring a consistent and secure seal every time. Take note of the machine's heating time as well. Machines with quicker heating times can help improve efficiency in a busy commercial setting.

Tip: Always check for user reviews and product specifications to assess the durability and reliability of a heat sealer. Investing in a quality machine can reduce long-term costs associated with repairs and maintenance.

Moreover, consider safety features such as automatic shut-off options and protective covers. These features not only enhance user safety but also prevent overheating, extending the lifespan of the machine. Lastly, evaluate the maintenance requirements; a machine that is easy to clean and maintain will save you time and effort in the long run.

2025 Guide: Key Features to Consider When Selecting a Heat Sealer Machine

Assessing the Right Size and Capacity for Your Business Needs

When selecting a commercial heat sealer machine, understanding the appropriate size and capacity for your specific business needs is crucial. According to industry reports, businesses in sectors such as food packaging, pharmaceuticals, and electronics have varying requirements based on their production volumes and product sizes.

For instance, a small-scale operation might require a heat sealer that can process 10-15 units per minute, while larger manufacturers may need machines capable of sealing 40+ units per minute to keep up with high demand.

Tips: Evaluate your production goals and choose a machine that fits not only your current needs but also offers scalability for future growth. Select a heat sealer that matches the dimensions of your products. Machines with adjustable settings can save both time and resources as they accommodate different packaging requirements.

Additionally, it's important to consider the material of the items being sealed. If your business commonly packages products in varying sizes or requires custom forms, opting for a versatile heat sealer with adjustable temperature and sealing width can optimize both efficiency and output.

A report by the Flexible Packaging Association indicates that machines with flexible capabilities can increase productivity by up to 20%, making them a worthwhile investment for businesses looking to enhance operational efficiency.

Evaluating Cost vs. Quality: Finding the Best Value Heat Sealer

When choosing the best commercial heat sealer machine, it's essential to evaluate the cost versus the quality of the equipment. While it's tempting to opt for a lower-priced machine, long-term savings often come from investing in high-quality sealers. Quality machines tend to offer better durability, efficiency, and performance, which can ultimately enhance productivity and reduce operational costs. A reliable heat sealer can ensure that packaging remains intact and secure, minimizing waste and the potential for product loss.

**Tips:** Consider conducting thorough research on various machines in the market. Look for user reviews, as well as ratings based on performance and longevity. Additionally, assess the warranty and customer support provided, as these factors can greatly influence your overall satisfaction and peace of mind with your purchase.

Another critical aspect to consider is the intended use of the heat sealer. Different applications may require specific features; for instance, higher-volume production might necessitate a faster sealing speed. Balancing these needs against your budget is key to finding the best value. Often, investing in machines with additional features, like adjustable temperature settings, can lead to more consistent results and greater versatility in your sealing operations.

**Tips:** Make a list of essential features you need based on your specific applications. This can help streamline your decision-making process and ensure that you don’t compromise on quality while staying within budget.

Maintenance Tips for Longevity and Performance of Heat Sealers

Maintaining a commercial heat sealer machine is essential for ensuring its longevity and optimal performance. Regular cleaning is crucial, as residues from previous sealing processes can accumulate and impair functionality. It is advisable to use a soft cloth and appropriate solvents to wipe down the sealing area and any other accessible surfaces. Properly inspecting the sealing jaws for wear or damage will also help in detecting potential issues early, preventing costly repairs and downtime.

Additionally, routine checks of the electrical components and power connections are vital. Ensure that all cords are intact and clean, and that there are no loose connections which could lead to power failures. Lubrication of moving parts, following manufacturer guidelines, can prevent friction-related wear. Furthermore, utilizing the heat sealer exclusively for its intended purpose and adhering to usage limits will greatly enhance its lifespan and efficiency, allowing businesses to benefit from consistent, high-quality sealing results.