Top Benefits of Using Industrial Heat Sealing Machines for Your Business

The industrial heat sealing machine has revolutionized packaging and manufacturing processes across various industries. According to a recent report by MarketsandMarkets, the global packaging machinery market, which includes heat sealing technology, is projected to reach USD 50.6 billion by 2025, growing at a CAGR of 4.4%. This growth is driven by the increasing demand for efficient packaging solutions, particularly in the food, beverage, and pharmaceutical sectors. The precision and reliability of industrial heat sealing machines ensure that products remain intact and undamaged during transit, ultimately enhancing customer satisfaction and reducing waste.

Industry expert Dr. Jane Smith, who specializes in packaging technologies, emphasizes the importance of adopting modern sealing methods: “The utilization of advanced industrial heat sealing machines not only improves the quality of product sealing but also enhances production efficiency.” This technology allows businesses to automate their packaging processes, resulting in significant time and cost savings. Furthermore, the ability to customize sealing parameters according to different materials and product specifications makes industrial heat sealing machines an indispensable asset for any manufacturing firm looking to optimize operations and stay competitive in today's fast-paced market.

In conclusion, as industries continue to evolve, embracing innovative solutions like industrial heat sealing machines will be paramount for achieving operational excellence and driving business growth.

Benefits of Enhanced Packaging Durability with Heat Sealing Machines

Enhanced packaging durability is a critical factor for businesses aiming to improve product protection and consumer satisfaction. Industrial heat sealing machines play a pivotal role in achieving this objective by creating airtight and tamper-proof seals that significantly extend the shelf life of packaged goods. According to a report by MarketsandMarkets, the global packaging industry is projected to reach $500 billion by 2024, with heat sealing technology being a leading contributor to this growth due to its ability to enhance product integrity and reduce spoilage.

Moreover, utilizing heat sealing machines can reduce the reliance on additional packaging materials. Research from the Flexible Packaging Association shows that over 70% of consumers prefer environmentally friendly packaging, driving the demand for efficient sealing methods that minimize waste. Heat sealing machines not only improve sealing strength but also offer versatility across different materials, enabling businesses to adapt to market trends that favor sustainable practices while maintaining product durability. This combination of improved packaging performance and alignment with consumer preferences positions businesses for success in a competitive market.

Top Benefits of Using Industrial Heat Sealing Machines

This chart illustrates the top benefits of using industrial heat sealing machines for enhanced packaging. The percentages represent the impact of each benefit on businesses, showcasing how heat sealing improves durability, reduces waste, boosts efficiency, is cost-effective, and offers versatile applications.

Improved Efficiency and Productivity in Industrial Processes

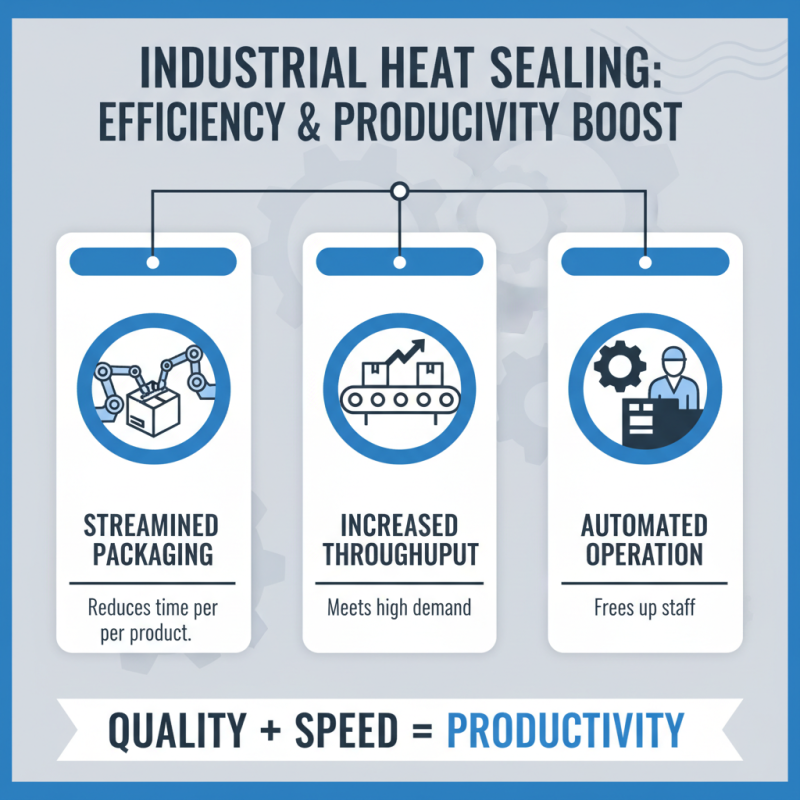

Industrial heat sealing machines play a pivotal role in enhancing efficiency and productivity across various sectors. By employing advanced sealing technologies, these machines streamline packaging processes, significantly reducing the time required to seal products securely. In fast-paced industrial environments, this efficiency translates into higher throughput rates, allowing businesses to meet increasing demand without compromising quality. With automation features, operators can focus on other crucial tasks while the machines efficiently seal and package products, thus boosting overall productivity.

Moreover, the consistency and reliability of heat sealing machines minimize the likelihood of product defects, further enhancing operational efficiency. Flawless sealing reduces the chances of product contamination and increases shelf life, which is essential in industries such as food and pharmaceuticals. The quick transition between different packaging styles and sizes ensures flexibility, enabling businesses to adapt to changing market demands swiftly. Overall, the integration of industrial heat sealing machines into production lines signifies a strategic move towards optimizing processes and achieving higher productivity levels.

Cost-Effectiveness of Using Industrial Heat Sealing Machines

The cost-effectiveness of using industrial heat sealing machines is a significant concern for businesses aiming to enhance their packaging operations. According to a recent report by MarketsandMarkets, the global packaging machinery market is projected to grow to $45 billion by 2025, driven largely by the increasing demand for efficient and streamlined packaging solutions. Industrial heat sealing machines play a pivotal role in this growth, providing high-speed sealing capabilities that reduce labor costs and minimize material wastage.

By implementing heat sealing technology, companies can achieve consistent seals for a variety of materials with high precision. This not only enhances product protection but also significantly cuts down on the costs associated with faulty packaging. The International Society of Packaging Engineers (ISPE) estimates that businesses can save up to 20% in packaging costs when switching to automated heat sealing processes, thanks to increased throughput and reduced raw material use. Furthermore, these machines require less energy compared to traditional sealing methods, contributing to lower operational expenses over time. As companies strive for sustainability, the energy efficiency of heat sealing machines presents an attractive benefit, aligning cost savings with eco-friendly practices.

Top Benefits of Using Industrial Heat Sealing Machines for Your Business - Cost-Effectiveness of Using Industrial Heat Sealing Machines

| Benefit |

Description |

Cost Savings (%) |

Efficiency Improvement (%) |

| Enhanced Packaging Integrity |

Seals products securely, reducing spoilage and returns. |

15% |

20% |

| Speed of Production |

Faster sealing processes lead to quicker production times. |

10% |

30% |

| Reduced Labor Costs |

Automated sealing reduces the need for manual labor. |

20% |

15% |

| Versatility |

Can handle various types of materials and products. |

5% |

10% |

| Low Maintenance Costs |

Heat sealers typically require less maintenance than other systems. |

12% |

5% |

Versatility in Applications Across Different Industries

Industrial heat sealing machines offer a remarkable level of versatility, making them invaluable across a variety of industries. In packaging, they ensure airtight seals that preserve the quality and freshness of products, ideal for food and pharmaceutical sectors. Their ability to adapt to different materials, such as plastics, films, and foils, means that businesses can customize packaging solutions to meet specific needs, improving efficiency and reducing waste in the process.

Moreover, the versatility of heat sealing machines extends beyond traditional packaging applications. In the textile industry, they are used for sealing and joining fabrics, which enables the production of high-quality garments and goods with enhanced durability. Additionally, industries such as automotive and electronics benefit from these machines by creating packaging that protects sensitive components during shipping. This multifunctionality not only streamlines operations but also opens doors to innovative packaging designs, helping businesses maintain a competitive edge in their respective markets.

Environmental Benefits of Industrial Heat Sealing Solutions

Industrial heat sealing machines offer a multitude of benefits, particularly when considering their environmental impact. One significant advantage is their ability to enhance packaging efficiency, thereby reducing waste.

Traditional packaging methods often result in excess materials being used, which leads to more waste in landfills. By employing heat sealing technology, businesses can achieve tighter seals with minimal material usage, ultimately contributing to more sustainable packaging practices.

In addition to reducing material waste, industrial heat sealing solutions can also lower energy consumption. Modern machines are designed to operate with greater efficiency, consuming less power than older models or other sealing methods.

This not only helps in reducing operational costs for businesses but also diminishes their carbon footprint. Moreover, many heat sealing machines are now equipped with advanced features that utilize renewable energy sources, further promoting an eco-friendly approach to production.

Finally, heat sealing technology improves product longevity by creating airtight seals that protect contents from external elements, thus reducing spoilage and the need for additional preservatives. This aspect not only benefits the environment by minimizing food waste but also aligns with consumer preferences for sustainable and long-lasting products.

Overall, the adoption of industrial heat sealing machines presents significant environmental benefits that support both business efficiency and sustainability goals.