What is an Industrial Sealer Machine and How Does It Work?

Industrial sealing machines play a crucial role in various manufacturing processes. These machines ensure product integrity and extend shelf life. According to a recent report by MarketsandMarkets, the global sealing equipment market is projected to reach $10 billion by 2026, indicating a growing demand for efficient sealing solutions.

The functionality of an industrial sealer machine is simple yet essential. It seals products ranging from food to pharmaceuticals, preventing contamination. The technology involved often includes heat sealing, vacuum sealing, or adhesive application. However, many industries still face challenges in optimizing these machines. Issues like seal strength variability often lead to product waste.

Adopting a more innovative approach can improve performance. Regular maintenance and training for operators are vital. Many companies overlook these aspects, leading to inefficiencies. The industrial sealer machine is more than just a tool; it is a gateway to quality assurance in production lines.

Definition and Purpose of an Industrial Sealer Machine

An industrial sealer machine is essential in manufacturing and packaging industries. Its primary purpose is to create airtight seals on various packaging materials. This ensures product freshness and safety. It can seal bags, pouches, and boxes, meeting diverse needs in food, pharmaceuticals, and electronics. According to industry reports, the market for sealing machines is expected to grow significantly, driven by increased demand for packaged goods.

The functionality of an industrial sealer machine is relatively straightforward. It uses heat or pressure to bond materials together. For example, heat sealers apply high temperatures to thermoplastic packaging, resulting in strong seals. The efficiency of these machines is notable. A high-speed sealer can process up to 200 packages per minute. This capability helps manufacturers keep pace with market demands, but not all machines maintain consistent quality.

Despite advancements, challenges remain. Many machines require regular maintenance to avoid breakdowns and inefficiencies. Sealing defects can lead to product spoilage, impacting a company's reputation. Industry surveys reveal that up to 15% of sealed packages suffer from minor defects. This statistic stresses the importance of quality control in the sealing process. Therefore, businesses must invest in both technology and employee training to optimize performance.

Types of Industrial Sealer Machines and Their Applications

Industrial sealer machines are essential in various sectors. They ensure products are securely packaged. Different types of sealers cater to diverse applications.

One common type is the heat sealer. It uses heat to bond materials. This is ideal for plastic bags, pouches, and films.

Another type is the vacuum sealer. It removes air from packaging to extend shelf life. These are widely used in food industries.

Tips: Always choose a sealer based on your specific needs. Consider the materials you'll be sealing. Each type has its strengths and weaknesses. Regular maintenance is crucial for performance.

Impulse sealers are also popular. They work by applying pressure and heat briefly. This method is quick and efficient. However, they may not be suitable for thicker materials.

Tip: Before purchasing, test the machine's compatibility with your materials. Make sure to review user manuals carefully. Knowledge is key to effective use.

Key Components and Features of Industrial Sealer Machines

Industrial sealer machines play a crucial role in packaging processes across various industries. These machines are designed to provide airtight seals for products, ensuring freshness and safety. Key components include heating elements, pressure sealers, and conveyor systems. Each part works in harmony to deliver reliable sealing.

The heating element applies controlled heat, melting packaging materials to form a bond. Pressure sealers press the packaging, ensuring a tight fit. According to industry reports, improper sealing can lead to up to 30% product waste. This statistic emphasizes the importance of reliable machinery.

Features often include adjustable temperature settings and speed controls. These allow operators to customize the sealing process for different materials. However, maintenance remains a challenge. Regular checks are necessary to avoid breakdowns. A neglected machine can disrupt production. Long-term reliability requires constant attention to detail.

What is an Industrial Sealer Machine and How Does It Work?

| Component |

Description |

Functionality |

Materials Used |

| Heating Element |

Generates heat to create a seal. |

Melts the packaging material to form a seal. |

Plastic, foil, film materials. |

| Sealing Jaws |

Mechanical parts that hold and press the material. |

Ensures proper alignment and pressure during sealing. |

Steel, aluminum alloys. |

| Control Panel |

User interface for settings adjustments. |

Allows the operator to control sealing time and temperature. |

N/A |

| Conveyor System |

Moves products to and from the sealer. |

Automates the sealing process for high efficiency. |

N/A |

| Safety Features |

Includes emergency shutoff and guards. |

Protects operators from injury. |

N/A |

How Industrial Sealer Machines Operate: Step-by-Step Process

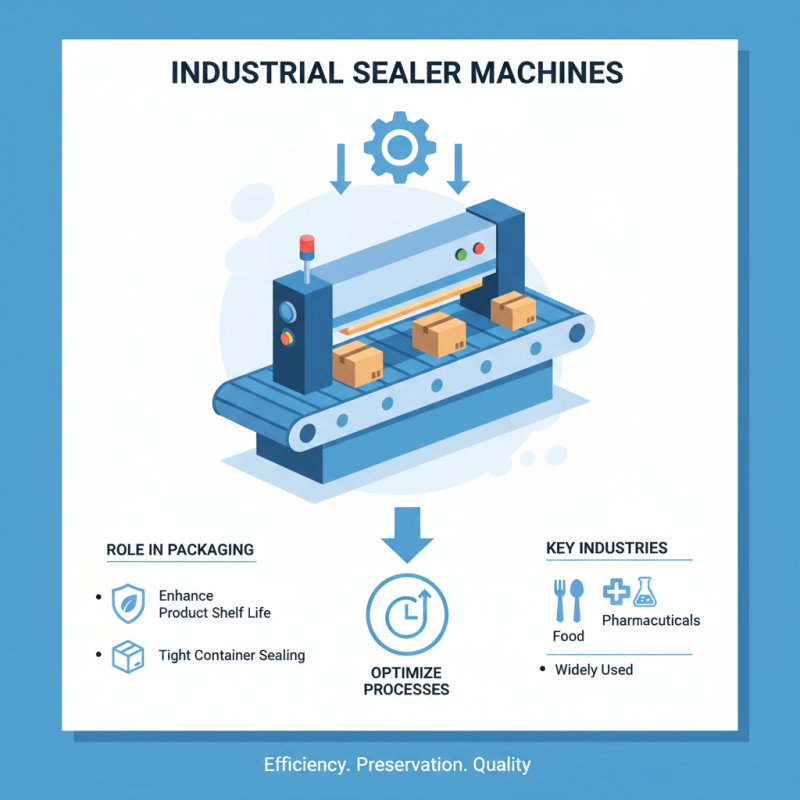

Industrial sealer machines play a vital role in packaging. They enhance product shelf life by sealing containers tightly. These machines are widely used in various industries, including food and pharmaceuticals. Understanding their operation can help businesses optimize processes.

The operation of an industrial sealer machine involves several steps. First, the operator places the product in a container. Then, the machine uses heat, pressure, or adhesives to create a secure seal. Often, automated versions can handle multiple products simultaneously, increasing efficiency. The sealing cycle typically takes just a few seconds. However, users must ensure proper calibration to avoid issues, like leaks or improper seals.

In practice, mistakes can happen. Sometimes operators misload containers, leading to inconsistent sealing. Additionally, machine maintenance is crucial. Neglect can cause malfunctions, resulting in product waste. Testing seals should become a routine to guarantee quality. Each of these factors requires attention to detail for effective sealing operations.

Maintenance and Safety Considerations for Industrial Sealers

Maintenance is crucial for industrial sealers to function reliably. Regular inspections help identify wear and tear. Inspect seals, belts, and components for any signs of damage or wear. Different materials require distinct maintenance methods. A small oversight can lead to major issues down the line.

Tips: Always keep a maintenance log. This helps track repairs and replacements over time. Cleaning the machine regularly reduces dust accumulation. This simple act can increase efficiency significantly.

Safety is equally important. Operators must wear appropriate safety gear. This includes gloves and goggles to protect against possible splashes. Understanding the machine's operation is vital. Improper use can lead to accidents or damage. Ensure all employees receive proper training on safety protocols.

Tips: Create a safety checklist for every shift. This should include checking emergency shutoffs and safety guards. Regular safety drills can improve awareness and preparedness. Keep first aid kits readily available near the workstation.

Usage of Industrial Sealer Machines Across Different Industries